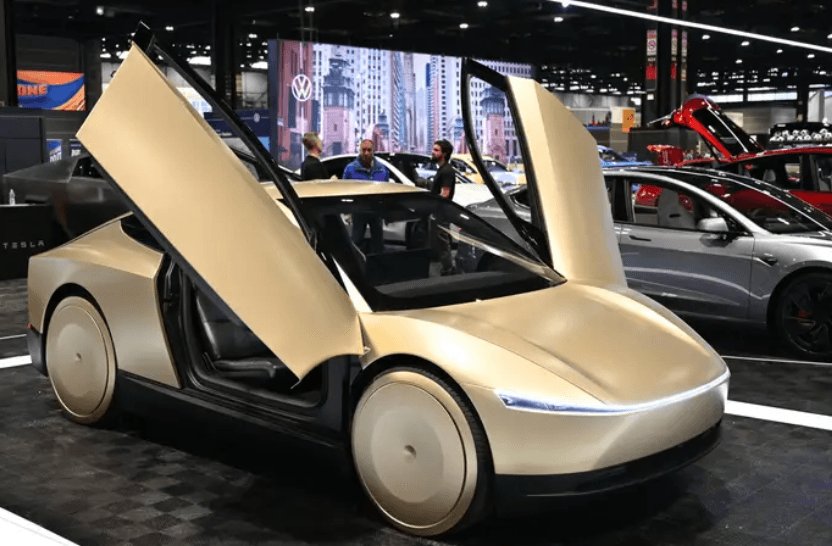

On February 17, 2026, Tesla announced that its first production Cybercab had officially rolled off the assembly line at Gigafactory Texas. The company shared a photo of employees gathered around a gold-colored two-seater with butterfly doors, celebrating a milestone that CEO Elon Musk has called critical to Tesla’s future.

Here’s the thing, though: this vehicle has no steering wheel. No pedals. No way for a human to take control if something goes wrong.

And the software that’s supposed to drive it autonomously? It doesn’t work yet. Not reliably, anyway.

Welcome to one of the most audacious or reckless, depending on your perspective product bets in automotive history. Tesla is manufacturing a vehicle that literally cannot function unless technology that doesn’t exist yet gets perfected. And they’re doing it right now, with mass production scheduled to begin in April 2026.

Let me explain why this is either genius or madness, and why you should be paying very close attention either way.

What Actually Just Happened

The basics first: Tesla produced the first manufacturing-ready Cybercab at its Austin, Texas gigafactory. This is not a concept vehicle or a hand-built prototype. This is the first unit to come through the actual production process that Tesla plans to scale up starting in April.

What is the Cybercab?

- A two-passenger electric robotaxi

- Designed to operate entirely on Tesla’s Full Self-Driving (FSD) software

- No steering wheel, no pedals, no manual controls of any kind

- Butterfly-style doors (like a fancy sports car)

- Wireless inductive charging (no plug-in port)

- Projected price: under $30,000

- Target production rate: one vehicle every 10 seconds (eventually)

The Cybercab was first unveiled at Tesla’s “We, Robot” event in October 2024, where 20 prototypes gave rides to attendees around the Warner Bros. Studios lot in Burbank. Now, 16 months later, the first production unit exists.

Elon Musk confirmed on X that volume production will begin in April 2026, though he warned it would start “agonizingly slow” because “almost every part and process in the Cybercab is new.”

The Problem Nobody Wants to Talk About

Here’s where things get uncomfortable: Tesla’s robotaxi software isn’t ready. Not even close.

Let’s look at the actual data from Tesla’s current robotaxi pilot program in Austin, which launched in June 2025 using modified Model Y vehicles equipped with the same FSD technology that’s supposed to power the Cybercab.

The Austin Robotaxi Reality Check:

- 40 vehicles operating

- 8 months in service

- Approximately 800,000 cumulative miles driven

- 14 crashes

- Crash rate: one every 57,000 miles

For context, human drivers in the US average one crash every 250,000-300,000 miles. Tesla’s robotaxis are crashing at nearly four times the rate of human drivers.

The availability rate? 19%. That means these robotaxis are only operational and available for rides about one-fifth of the time.

And here’s the kicker: when Tesla briefly removed safety drivers from these robotaxis in late January 2026 to test “unsupervised FSD,” they had to deploy trailing safety cars vehicles following behind with human operators ready to intervene remotely. That’s not autonomy. That’s remote control with extra steps.

Elon’s Own Admission: “We Need 10 Billion Miles”

In January 2026, Musk himself stated that Tesla needs approximately 10 billion miles of FSD data to achieve “safe unsupervised self-driving.”

Based on current fleet growth and FSD engagement rates, Tesla is projected to reach that data milestone around July 2026. That’s three months after mass production of the Cybercab is supposed to begin.

But here’s the thing: collecting the data is only step one. Tesla still needs to:

- Run massive training runs on that data

- Conduct extensive validation testing

- Debug millions of edge cases

- Validate safety across diverse scenarios

Industry estimates suggest that even after collecting 10 billion miles of data, the software won’t be ready for unsupervised deployment for at least another year beyond that. We’re talking mid-to-late 2027 before FSD might actually be safe enough for truly autonomous operation.

Meanwhile, Tesla is building vehicles right now that depend entirely on that non-existent capability.

The Hardware Problem: Launching on Old Chips

It gets worse. Tesla has delayed its next-generation AI5 chip to mid-2027. That means the Cybercab will launch with current-generation AI4 hardware.

This matters because autonomous driving is computationally intensive. More powerful chips can process more sensor data, make decisions faster, and handle edge cases better. Starting production on AI4 when AI5 is just around the corner creates a potential obsolescence problem.

What happens if AI5 turns out to be necessary for reliable autonomy? Does Tesla recall every Cybercab and retrofit them? Do early customers just live with less capable vehicles? It’s unclear.

The Manufacturing Revolution: “Unboxed” Production

Let’s talk about one genuinely innovative aspect of the Cybercab: how Tesla plans to build it.

Traditional car manufacturing uses a moving assembly line. Parts are added sequentially as the vehicle moves down the line. It’s been the standard approach since Henry Ford pioneered it over a century ago.

Tesla’s “unboxed” process is radically different. Instead of a linear assembly line, different modules of the vehicle are assembled simultaneously in separate areas of the factory, then brought together at the end for final integration.

Think of it like building with LEGO: instead of adding one brick at a time in sequence, you build multiple sections in parallel, then click them together.

The claimed benefits:

- 5x higher production rate potential

- Significantly less factory floor space required

- Lower manufacturing costs

- Faster ramp-up once the process is refined

The challenges:

- Completely unproven at scale

- Requires perfect coordination between modules

- Any issue in one module holds up the entire build

- Musk himself admits the early ramp will be “agonizingly slow”

A lead Tesla engineer previously stated that the Cybercab is expected to have 50% fewer parts than a Model 3. Fewer parts means simpler assembly, lower costs, and fewer things that can go wrong.

But it also means this is an entirely new manufacturing paradigm. Tesla is simultaneously trying to:

- Perfect autonomous driving software

- Launch a new vehicle with no manual controls

- Scale an entirely new manufacturing process

Any one of these would be challenging. All three at once? That’s either visionary or reckless, depending on how charitable you’re feeling.

The Regulatory Minefield

Here’s a fun fact: US Federal Motor Vehicle Safety Standards require vehicles to have steering wheels and pedals.

Tesla needs special exemptions to sell the Cybercab legally. They’re currently seeking these exemptions, but there’s no guarantee they’ll be granted. Regulators tend to be conservative about safety-critical systems, and “trust us, the software will work” isn’t typically a winning argument.

Robyn Denholm, Tesla’s chairwoman, hinted in January that the Cybercab might need a steering wheel after all. Musk quickly shut that down publicly, but Cybercab prototypes spotted testing in Austin late last year were equipped with steering wheels.

The California Department of Motor Vehicles nearly suspended Tesla’s sales license in February over misleading descriptions of its “Autopilot” and “Full Self-Driving” features. Tesla revised its language just in time to avoid the 30-day suspension. That’s not exactly a vote of confidence from regulators.

Tesla also hasn’t secured the “Cybercab” trademark yet. The company received a 30-day extension to oppose a squatter’s claim, pushing the deadline to March 14, 2026—less than a month before the stated production date.

If Tesla can’t secure the trademark, they might have to rename the vehicle entirely. Imagine launching a product without even finalizing what you’re allowed to call it.

The $30,000 Promise and the MKBHD Bet

Tesla has consistently stated the Cybercab will be priced under $30,000. That’s remarkable—a fully autonomous electric vehicle for less than a base Model 3.

But Tesla has a history of announcing low prices at unveiling events, then launching vehicles at significantly higher prices. The Cybertruck was originally projected at $39,900. It launched starting at $60,990.

Popular tech YouTuber Marques Brownlee (MKBHD), who has 20+ million subscribers, publicly bet in October 2024 that Tesla wouldn’t deliver a Cybercab for under $30,000 before 2027. He promised to “shave my head on camera” if they did.

On February 17, 2026, shortly after the first Cybercab rolled off the line, Musk responded to a video compilation of MKBHD’s comments with “Gonna happen :D” suggesting Tesla will indeed deliver on the sub-$30,000 price before 2027.

Whether that’s bravado or genuine confidence, we’ll find out soon enough. But given Tesla’s track record on pricing promises, healthy skepticism is warranted.

What Waymo Is Doing Differently (And Why It Matters)

Let’s contrast Tesla’s approach with Waymo, the company actually operating successful autonomous robotaxis at scale in multiple US cities.

Waymo’s approach:

- Uses lidar, radar, and cameras (redundant sensor systems)

- Operates in geofenced areas with detailed 3D maps

- Extensive pre-deployment testing with safety drivers

- Gradual, conservative rollout

- “Ghost rider” validation runs (empty vehicles driving around cities for months before launch)

- Transparent reporting of incidents and failures

Tesla’s approach:

- Cameras only (Tesla’s “pure vision” strategy)

- No geofencing operates anywhere

- Limited pre-deployment validation

- Aggressive rollout timeline

- Minimal public reporting on safety incidents

Electrek, which covers Tesla extensively, put it bluntly: “When ANY company with a real autonomous vehicle rolls out a service, they send their vehicles, with no people in them, to drive around a city doing validation runs. We see empty Waymos (‘ghost riders’) driving around all the time where I live preparing for their launch. You will know Tesla has an actual robotaxi when you see that. Not just one or two, but triple-digit empty taxis cruising the streets.”

As of mid-February 2026, that’s not happening. Tesla’s robotaxis still require trailing safety vehicles for unsupervised operation.

The Vision vs. Reality Gap

Elon Musk has a long history of ambitious autonomous driving predictions. Let’s review:

2017: Promised a fully autonomous cross-country drive from Los Angeles to New York. Didn’t happen.

2019: Stated Tesla would have one million autonomous robotaxis operating on public roads by the end of 2020. As of 2026, Tesla has about 40 robotaxis operating in Austin.

2020-2025: Predicted “Full Self-Driving” would be solved “next year” virtually every year. Still hasn’t happened.

2026: Claims the Cybercab will achieve mass production in April and operate without steering wheels or pedals.

There’s a pattern here. Musk’s vision for autonomous driving is genuinely ambitious and potentially transformative. His timelines, however, have been consistently wrong by years.

The question is: has Tesla actually solved the hard problems this time, or is the Cybercab another ambitious bet on technology that isn’t ready yet?

The Bull Case: Why This Might Actually Work

Let me steelman the optimistic perspective, because it’s not all doom and gloom.

Argument 1: Tesla has more real-world data than anyone.

Tesla’s FSD system is deployed across millions of vehicles worldwide. Every mile driven by a Tesla with FSD engaged generates training data. That’s vastly more diverse, real-world data than Waymo or any competitor has access to.

If autonomous driving is fundamentally a data problem and many experts believe it is then Tesla’s data advantage is enormous and growing exponentially.

Argument 2: The economics are compelling.

A $30,000 robotaxi with 50% fewer parts than a Model 3, manufactured using an unboxed process that’s 5x more efficient? If Tesla can actually execute on this, the unit economics could be revolutionary.

Traditional taxis require human drivers who get paid, take breaks, and limit operational hours. A robotaxi that operates 24/7, charges wirelessly, and costs a fraction of a traditional taxi to build? That could genuinely transform urban transportation.

Argument 3: Regulatory approval is likely eventual.

Even if initial regulatory hurdles delay deployment, governments worldwide want autonomous transportation to succeed. It promises fewer accidents, better traffic flow, increased mobility for elderly and disabled people, and reduced urban congestion.

Tesla might not get exemptions immediately, but over the next 2-3 years? Probably. The question is whether the technology is ready when the regulations allow it.

Argument 4: Manufacturing innovation de-risks other limitations.

Even if FSD takes longer than expected to perfect, the unboxed manufacturing process and simplified vehicle design are valuable in their own right. Tesla could potentially sell Cybercabs to other robotaxi operators, or even pivot to a rideshare model with human drivers initially while FSD matures.

The vehicle isn’t worthless if FSD doesn’t work immediately it’s just not as revolutionary as promised.

The Bear Case: Why This Could Be a Disaster

Now the pessimistic view:

Argument 1: This is a $30,000 paperweight if FSD doesn’t work.

A vehicle with no steering wheel and no pedals is literally unusable if the autonomous driving software fails. You can’t manually drive it. You can’t even move it in a parking lot. If FSD isn’t solved, every Cybercab built is wasted capital sitting in a warehouse.

Argument 2: The crash data is terrible.

Crashing at four times the rate of human drivers is disqualifying. No regulator will approve unsupervised operation with those statistics. Tesla needs to improve FSD dramatically, not incrementally.

Argument 3: Computer vision alone might not be enough.

Waymo, Cruise, and every other serious autonomous vehicle company uses lidar and radar in addition to cameras. Tesla’s “pure vision” approach is cheaper, but it might be fundamentally inadequate for safety-critical applications.

Humans drive with vision alone, but humans also crash constantly. If the standard is “dramatically safer than humans,” vision-only might not cut it.

Argument 4: The timeline is absurd.

Mass production in April 2026. Data collection milestone in July 2026. Software readiness by late 2027 at the earliest. The manufacturing is ahead of the technology by at least 18 months.

That’s not smart planning that’s building a product and hoping the critical enabling technology gets figured out later.

What Industry Experts Are Actually Saying

Let’s hear from people who aren’t Tesla employees or Tesla critics, just industry analysts trying to assess this rationally:

Electrek (long-time Tesla coverage site): “This is one of the most reckless product decisions in automotive history. Tesla is no longer talking about building a vehicle that cannot function unless software that doesn’t exist yet is perfected it’s actually doing it.”

Fred Lambert (Electrek editor): “The first Cybercab just rolled off the line. It has no steering wheel. It has no pedals. If FSD isn’t solved, this vehicle is a $30,000 paperweight on wheels.”

Industry analyst (unnamed, quoted by CNBC): “The regulatory path alone could take years. Building the vehicles before securing exemptions is putting the cart before the horse.”

A more optimistic take from TFLcar: “Tesla’s surprise kickoff of Cybercab production did temporarily boost its stock price to around $415 per share…Eventually, though, the company may end up selling them to private owners, potentially opening a new opportunity in mobility for people to get around who either can’t or don’t want to drive.”

The Stock Market’s Verdict: Temporary Enthusiasm, Lasting Skepticism

Tesla’s stock jumped briefly to $415 when the Cybercab production announcement dropped on February 17th. But within hours, it fell back to around $410 basically where it was before the announcement.

The market’s message is clear: this milestone is interesting but not transformative. Investors want to see actual deployment, safety validation, and regulatory approval before they get excited.

Tesla’s stock has gained 16% over the past 12 months solid, but not spectacular given the hype around robotaxis and autonomous driving.

For comparison, Waymo (owned by Alphabet) operates thousands of autonomous rides daily across multiple cities with a strong safety record. Alphabet’s stock has outperformed Tesla over the same period.

The market is waiting for Tesla to prove the technology works at scale, not just announce that manufacturing has started.

What Happens Next: The Critical Path to Launch

For the Cybercab to actually become a product people can use, Tesla needs to:

By April 2026:

- Ramp up production of vehicles (they’ve committed to this)

- Continue FSD data collection toward the 10 billion mile milestone

- Secure federal regulatory exemptions for steering wheel/pedal requirements

- Finalize the “Cybercab” trademark

By mid-late 2026:

- Demonstrate meaningful improvements in FSD crash rates

- Achieve the 10 billion mile data collection target

- Begin intensive validation testing of unsupervised FSD

- Potentially launch initial Cybercab service in Texas (which has more permissive regulations)

By 2027:

- Expand to additional markets if safety and regulatory requirements are met

- Scale production using the unboxed manufacturing process

- Deliver vehicles to customers (if the MKBHD bet is to be won)

- Potentially open sales to private buyers or fleet operators

That’s an aggressive timeline. Any one of those milestones slipping could cascade into broader delays.

The Bigger Picture: What This Means for Transportation

Step back from the Tesla-specific drama for a moment and think about what’s actually at stake here.

If autonomous robotaxis work whether from Tesla, Waymo, or someone else—urban transportation could change fundamentally:

- Car ownership might decline dramatically in cities

- Parking spaces could be repurposed for housing or green space

- Transportation costs could drop significantly

- Mobility for elderly and disabled people could improve

- Traffic accidents could plummet (if autonomy is actually safer)

- Entire industries (taxi drivers, truck drivers, delivery drivers) face disruption

The potential upside is enormous. The potential downsides technological unemployment, safety concerns, cybersecurity risks are equally significant.

Tesla’s aggressive bet on the Cybercab accelerates this timeline. If they succeed, the autonomous future arrives sooner. If they fail spectacularly, it might set the industry back by damaging public trust.

The Honest Assessment: Too Early to Know

Here’s my genuine take after reviewing all the available evidence: it’s too soon to call this either brilliant or insane with confidence.

What we know for certain:

- Tesla is manufacturing a vehicle that requires technology that doesn’t reliably exist yet

- Current FSD performance in Austin is significantly worse than human drivers

- Regulatory approval is uncertain

- The manufacturing approach is innovative but unproven at scale

- The timeline is aggressive to the point of being unrealistic

What we don’t know:

- How quickly FSD will actually improve with more data

- Whether computer vision alone is sufficient for safe autonomy

- What the regulatory environment will look like in 12-24 months

- Whether the unboxed manufacturing process will deliver the promised efficiency gains

- If Tesla has internal data showing FSD improvements we haven’t seen publicly

If I had to bet, I’d say:

- The Cybercab will begin production in April as promised

- Initial production will be very slow (tens of vehicles, not thousands)

- Full autonomy won’t be approved for at least 18-24 months

- Early Cybercabs might operate with human remote monitors or even retrofit steering wheels

- The $30,000 price point might slip or come with significant caveats

- True unsupervised robotaxi service at scale is still 3-5 years away

But I could be completely wrong. Tesla has surprised skeptics before. The company went from near-bankruptcy in 2018 to becoming the most valuable automaker in the world. They’ve defied predictions repeatedly.

Maybe FSD improves dramatically faster than anyone expects. Maybe regulators, seeing Waymo’s success, become more permissive. Maybe the unboxed manufacturing process works flawlessly from day one.

Or maybe this is a $30,000 paperweight that sits in warehouses while Tesla frantically tries to make software work that should have been solved before production started.

What You Should Actually Watch For

If you want to know whether Tesla’s Cybercab bet will pay off, here are the signals that matter:

Signal 1: Ghost riders in Austin. When you start seeing dozens of empty Cybercabs driving around Austin with no trailing safety vehicles, that’s when Tesla has real autonomy. Not before.

Signal 2: Crash rate improvements. If Tesla’s Austin robotaxi crash rate drops from one per 57,000 miles to one per 250,000+ miles, that’s meaningful progress. If it stays high or gets worse, that’s disqualifying.

Signal 3: Regulatory approvals. Watch for NHTSA (National Highway Traffic Safety Administration) decisions on Tesla’s exemption requests. Approval signals confidence in the technology. Rejection means serious delays.

Signal 4: Production ramp. Is Tesla building 10 Cybercabs per month, or 1,000? The speed of the production ramp will tell you how confident they are in the technology being ready.

Signal 5: Third-party safety testing. Independent testing by organizations like Consumer Reports, IIHS, or university research groups. If they validate Tesla’s safety claims, that matters more than company announcements.

The Bottom Line

Tesla’s first Cybercab rolling off the production line is historic. It’s either the beginning of a transportation revolution or one of the most audacious product failures in automotive history.

The vehicle itself is genuinely innovative: two seats, butterfly doors, wireless charging, radically simplified manufacturing, projected $30,000 price. If the autonomous driving works, it could transform urban mobility.

But that’s a huge “if.” Tesla is building vehicles that depend entirely on software that doesn’t reliably exist yet, crashes at four times the rate of human drivers, and won’t be ready for at least 18-24 months by most estimates.

Manufacturing a product before the core enabling technology works is either visionary confidence or reckless hubris. We’ll know which in the next 12-18 months.

For now, the first production Cybercab exists. It’s beautiful, innovative, and completely unusable until Tesla solves problems they’ve been promising to solve “next year” for nearly a decade.

April 2026 is when mass production supposedly begins. July 2026 is when Tesla hits its 10 billion mile data target. Late 2027 is when the software might actually be ready.

The world is watching. Regulators are skeptical. Competitors are advancing their own solutions. And somewhere in Austin, empty Waymo robotaxis are driving around flawlessly, demonstrating what “solved” autonomous driving actually looks like.

Tesla’s bet is that they can get there faster by scaling manufacturing first and perfecting software in parallel. History will judge whether that was genius or madness.

Either way, it’s going to be fascinating to watch.

The first production Tesla Cybercab rolled off the line at Gigafactory Texas on February 17, 2026. Mass production is scheduled to begin in April 2026. Regulatory approval and software validation remain pending.

Leave a Reply